Tire Maintenance & Safety

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

Radial tires have revolutionized the automotive industry since their widespread adoption in the 1970s, becoming the standard for nearly all passenger vehicles on the road today. This advanced tire technology offers drivers superior performance, fuel efficiency, and longevity compared to older tire designs.

Understanding radial tire construction helps car owners make informed decisions about their vehicle's most critical safety component—the only part that actually touches the road. The unique engineering behind radial tires directly impacts everything from your daily commute comfort to your vehicle's fuel consumption.

Modern tire technology has evolved significantly from the early days of automotive travel, with radial construction representing one of the most important innovations in tire design. This construction method fundamentally changed how tires perform, last, and contribute to overall vehicle safety.

What is Radial Tire Construction?

Understanding the Basics

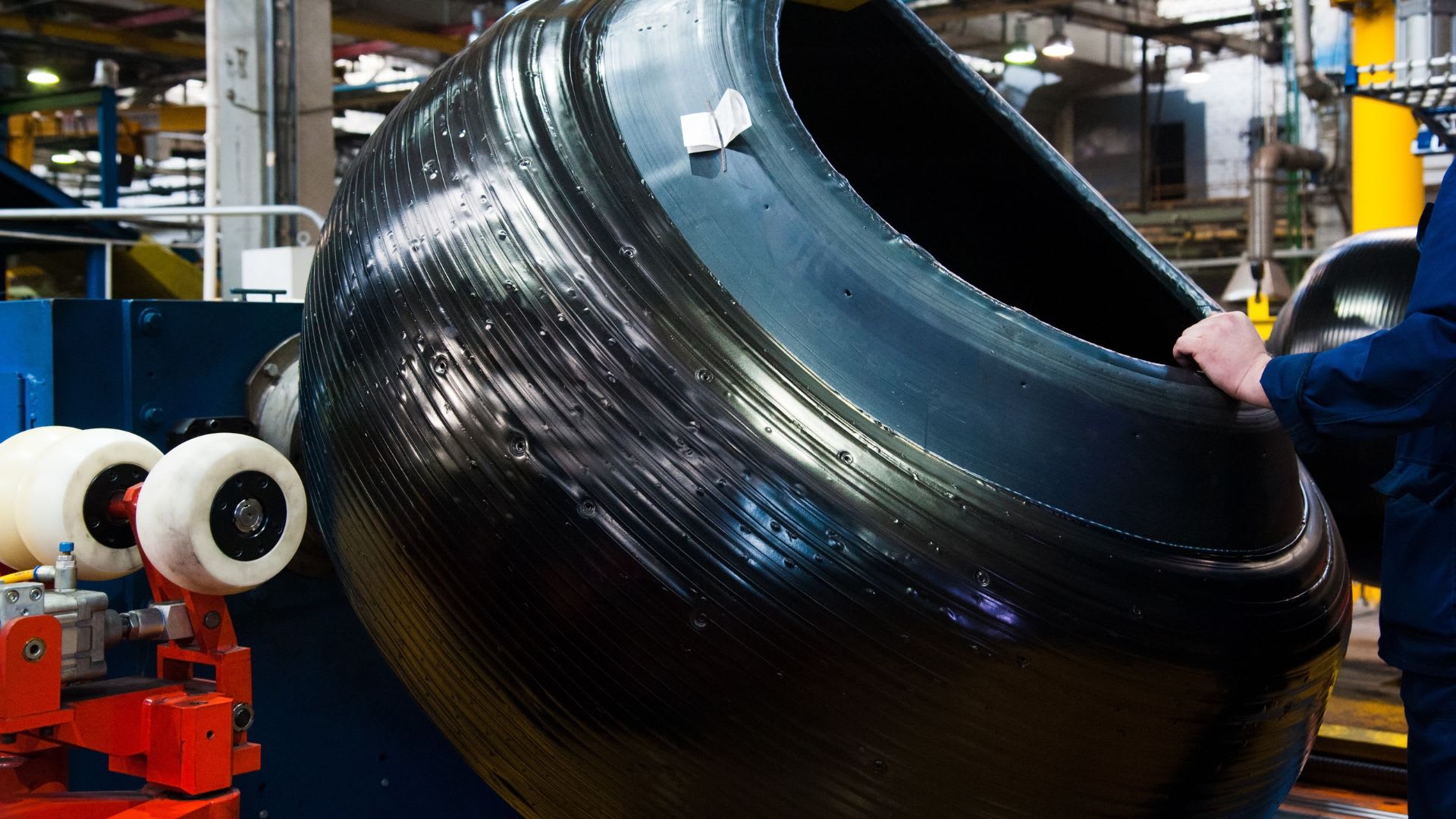

Radial tire construction represents a significant departure from traditional tire building methods. The defining characteristic of radial tires lies in their cord arrangement: steel cords run perpendicular from one sidewall to the other at 90-degree angles to the direction of travel. These cords lay parallel to each other, creating a tire structure that combines flexibility with exceptional strength.

The engineering brilliance of radial design allows the sidewall and tread areas to function independently—a key innovation that transformed tire performance. Steel belts positioned directly beneath the tread surface provide additional structural integrity and stability. This separation of functions means the sidewalls can flex to absorb road imperfections while the tread maintains consistent contact with the pavement.

Key Components of Radial Tire Anatomy

The sophisticated anatomy of a radial tire consists of several critical components working in harmony:

- Steel Belt Package: Multiple steel belts reinforce the tread area, creating a stable platform that resists deformation during cornering and braking. These belts maintain the tire's shape under various loads and speeds.

- Flexible Sidewalls: The radial ply arrangement allows sidewalls to act as vertical springs, providing superior ride comfort. This flexibility absorbs road irregularities without transmitting harsh impacts to the vehicle's suspension.

- Inner Liner: A specialized rubber compound forms an airtight barrier inside the tire, eliminating the need for inner tubes. This liner maintains proper inflation pressure while preventing air molecules from seeping through the tire structure.

- Bead Construction: High-strength steel wires wrapped in rubber form the bead area, ensuring secure mounting on the wheel rim. The bead must withstand tremendous forces during operation while maintaining an airtight seal.

- Body Plies: Polyester or other textile cords form the tire's foundation, running from bead to bead. These plies provide the basic structure while allowing the flexibility that defines radial tire performance.

- Tread Compound: Specially formulated rubber compounds create the road-contacting surface, engineered for specific performance characteristics such as wet traction, wear resistance, or low rolling resistance.

Each component plays a vital role in delivering the performance advantages that have made radial tires the industry standard. The precise engineering and material selection in modern radial tires result from decades of research and development, creating products that balance numerous competing demands: comfort versus handling, durability versus performance, and cost versus capability.

How Are Radial Tires Different from Bias Ply Tires?

Radial vs Bias Ply Construction

Radial and bias ply tires exhibit distinct differences in their structural design. Radial tires employ cords that extend across the tire from one bead to the other at right angles to the tread direction. This configuration allows the sidewalls to operate independently from the tread, enhancing flexibility and reducing heat buildup.

Bias ply tires, however, feature cords laid diagonally, crisscrossing at angles between 30 and 45 degrees. This pattern binds the sidewalls and tread into a unified structure, resulting in a stiffer tire. While this rigidity offers certain advantages, it also means that bias ply tires are less adept at dissipating heat, potentially impacting their overall longevity and efficiency.

Performance Differences

The distinct construction of radial tires translates into notable performance benefits. With reduced rolling resistance, radial tires contribute to improved fuel efficiency, offering drivers more miles per gallon. The design ensures even tread wear, which prolongs the tire's useful lifespan and maintains optimal performance over time.

Radial tires provide superior stability and handling, particularly at higher speeds, due to their design. The flexible sidewalls allow for better road contact, enhancing traction and control in various driving conditions. While bias ply tires might excel in certain demanding environments, radial tires generally offer a smoother ride and more reliable performance for everyday use.

What Are the Main Benefits of Radial Tires?

Fuel Efficiency and Cost Savings

Radial tires excel in reducing overall operational costs by leveraging their advanced design. The unique alignment of radial cords minimizes energy loss, allowing vehicles to operate more efficiently, which in turn supports reduced fuel consumption. This feature not only helps in saving money but also contributes to a greener planet by lowering emissions.

The construction of radial tires effectively manages heat, significantly enhancing their lifespan. By maintaining cooler operating conditions, these tires experience less degradation over time, ensuring that they remain reliable for longer periods. This durability maximizes the value of your investment, with the tires maintaining performance integrity throughout their extended service life.

Though radial tires might initially seem pricier, their long-term economic advantages are evident. The extended tread life and efficient fuel usage combine to offset the initial expense. Over time, this makes radial tires a cost-effective option for drivers looking to optimize their tire-related expenditures.

Comfort and Performance Benefits

The advanced design of radial tires ensures exceptional comfort. Their structure allows them to conform to road surfaces, smoothing out the ride and significantly enhancing comfort on varied terrains. This leading-edge design reduces the impact of road imperfections, providing a more pleasant driving experience.

Radial tires also offer excellent precision and control. Their construction supports consistent road contact, enhancing grip and stability. This ensures that drivers enjoy improved maneuverability and confidence, whether navigating city streets or open highways.

When it comes to versatility, radial tires deliver consistent performance across a range of conditions. From wet roads to dry highways, they maintain excellent traction and handling, making them a reliable choice for those seeking a tire that performs well regardless of the driving environment.

What Materials Are Used in Radial Tire Construction?

Steel Belted Radial Features

Radial tires owe their robustness to the integration of steel belts, which are strategically placed below the tread to enhance the tire's strength and consistency. These belts ensure the tire maintains its form and stability, crucial for handling various driving conditions with ease and efficiency.

Beyond steel, radial tires incorporate advanced materials such as nylon, rayon, and high-strength synthetic fibers. Nylon contributes elasticity and resilience, while rayon provides added strength and durability. These materials work synergistically to create a tire capable of handling the diverse demands of modern driving scenarios, delivering a comfortable and secure ride.

The rubber compounds in radial tires are expertly crafted to suit different driving needs. Whether it's for high-performance, all-weather adaptability, or rugged terrain, these compounds optimize the tire's grip and resilience, ensuring it performs exceptionally in its respective category. By fine-tuning the rubber mix, manufacturers enhance the tire’s ability to adapt to varied driving environments.

Advanced Material Benefits

The modern materials utilized in radial tire construction deliver numerous advantages that extend beyond durability. Steel belts offer exceptional resistance against punctures, maintaining the tire's integrity and ensuring reliable performance on the road. This stability is crucial for ensuring consistent handling and maximizing fuel efficiency.

Reinforced fibers like nylon and rayon play a pivotal role in preserving tire pressure by minimizing deformation under stress. This not only extends tire life but also supports optimal performance and fuel efficiency. Proper pressure maintenance is essential for reducing emissions and promoting more sustainable driving.

The specialized rubber compounds enhance the tire's adaptability across different weather conditions, providing superior traction on both wet and dry surfaces. Designed to withstand extreme temperatures, these compounds ensure the tire performs reliably, offering drivers peace of mind regardless of the climate. This versatility makes radial tires a steadfast choice for diverse driving conditions, maintaining traction and safety in any weather.

How Does Radial Tire Construction Affect Performance?

Handling and Stability

Radial tires provide exceptional handling characteristics due to their innovative construction. The cords in radial tires allow the tread to maintain a broader surface area in contact with the road, which enhances grip and stability. This design supports agile maneuvering and precise steering response, making it easier to navigate turns with confidence. Additionally, the flexible sidewalls contribute to a smoother transition during cornering, ensuring a balanced ride.

Enhanced braking performance is another advantage of radial tires. The consistent tread pattern delivers reliable traction during braking, helping to reduce stopping distances effectively. Moreover, the structural integrity of radial tires minimizes deformation even under high-speed conditions, preserving their shape and performance for a dependable driving experience.

Traction and Safety Features

Radial tires excel in delivering robust traction across diverse driving conditions. The tread design effectively channels away water, reducing the risk of hydroplaning and maintaining solid grip on wet roads. This capability ensures that drivers feel secure even when the weather turns challenging, providing stability and control.

One of the critical features of radial tires is their ability to manage heat efficiently. The construction facilitates optimal heat dissipation, which safeguards against overheating and enhances the tire's longevity. This thermal management not only preserves the tire's structural integrity but also contributes to consistent performance across various temperatures.

The design of radial tires supports predictable handling, offering drivers a reliable and responsive driving experience. At highway speeds, these tires provide enhanced stability, allowing for smooth and controlled travel. This stability, coupled with the tire's ability to maintain pressure and shape, ensures that radial tires can meet the demands of both everyday commuting and long-distance travel.

Are All Modern Tires Radial Construction?

Current Tire Market Trends

Radial tires dominate the current automotive landscape, becoming the go-to choice for nearly every passenger vehicle thanks to their superior design and performance attributes. This widespread preference highlights the efficiency and reliability that radial tires offer, making them indispensable for everyday driving needs across various vehicle types.

For light trucks and SUVs, radial designs provide enhanced durability and stability, crucial for handling the demands of larger, heavier vehicles. The emphasis on radial technology in these segments aligns with consumer expectations for vehicles that deliver exceptional performance and safety over diverse terrains and conditions.

However, bias-ply tires retain a foothold in certain specialized applications. These tires are favored in roles where their distinctive characteristics—such as increased resistance to certain types of wear and tear—offer tangible benefits. Meanwhile, radial technology continues to gain traction in commercial sectors, valued for its ability to reduce operational costs through improved longevity and fuel efficiency.

When Bias Ply Tires Are Still Used

Bias-ply tires remain relevant for specific tasks where their robust construction offers advantages. In the realm of heavy equipment and construction vehicles, these tires excel by providing resistance to punctures and damage, making them ideal for challenging work environments where durability is key.

Certain trailers benefit from the sway resistance offered by bias-ply tires, which enhances stability during transport. This feature is particularly advantageous for trailers carrying substantial or uneven loads, ensuring safer and more controlled towing.

In vintage vehicle restorations, maintaining historical accuracy is crucial, and bias ply tires help preserve the authentic look and feel of classic automobiles. Enthusiasts often choose these tires to retain the original driving characteristics and aesthetics of historic vehicles.

Off-road and agricultural vehicles continue to utilize bias ply tires for their ability to withstand rugged terrains. The construction of these tires offers the necessary traction and toughness needed to navigate the demanding landscapes encountered in these sectors, showcasing their enduring utility.

How to Identify Radial Tires on Your Vehicle

Reading Tire Sidewall Markings

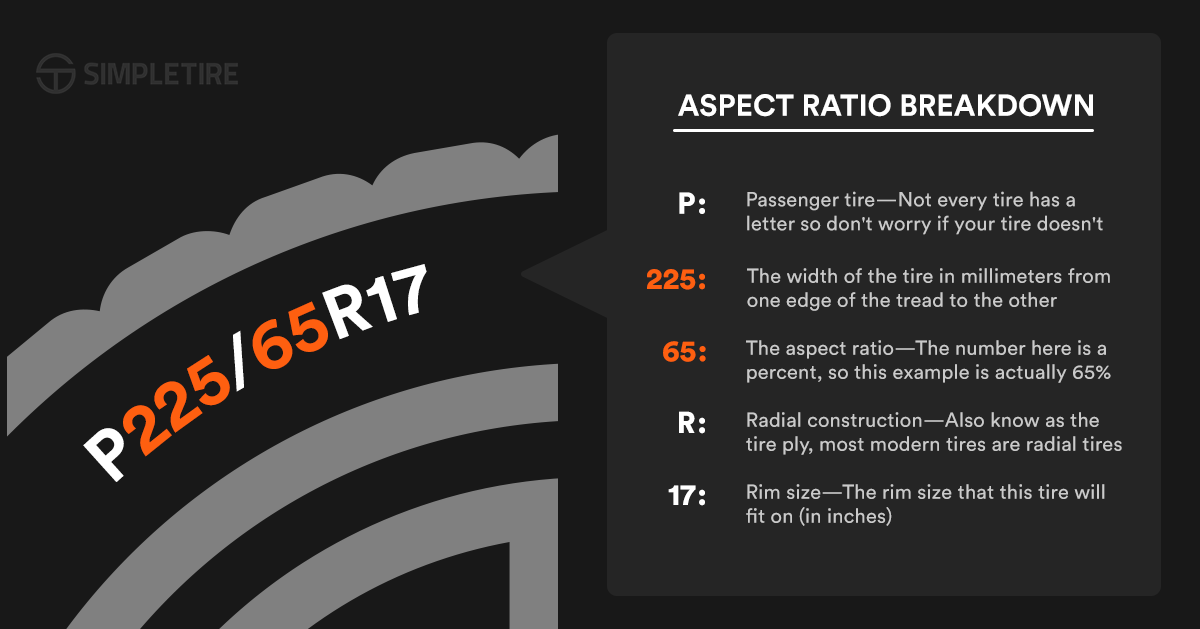

To determine if your vehicle's tires are radial, start by checking the sidewall for specific indicators. The sidewall displays crucial data, including the construction type of the tire. Locate the letter "R" in the tire size, such as in 205/65R15, which signifies radial construction. This letter distinguishes radial tires from other types.

If the "R" is missing, it may suggest an alternative construction, possibly bias-ply. Refer to your vehicle's door jamb sticker or the owner's manual to verify the manufacturer's recommended tire specifications. These sources provide essential guidance on choosing the correct tire type and size to match the vehicle's design requirements.

Visual Identification Tips

There are visual cues that can help confirm radial tires on your vehicle. Radial tires often show a noticeable curve at the sidewall, indicative of their inherent flexibility. This curve is more evident than in the rigid sidewalls of bias ply tires, reflecting the design that sets radial tires apart.

The tread pattern on radial tires tends to run directly across the tire, promoting consistent road contact and even wear. When pressure is applied, radial tires demonstrate a distinctive flexibility in the sidewall, contributing to their comfortable ride and handling. If you're unsure, tire professionals at modern shops can provide clarity on your tire construction type, ensuring you have the right fit for your driving needs.

Making the Right Tire Choice for Your Vehicle

Consider Your Driving Needs

Understanding your driving habits is essential when selecting the right tires. For daily commutes, radial tires provide a smooth and efficient ride, thanks to their advanced design that minimizes rolling resistance. This efficiency is particularly beneficial for urban drivers who rack up miles within city limits. If your travels often take you on highways, radial tires deliver the stability and control you need for high-speed journeys, enhancing safety and comfort.

For those who require versatility, radial tires are suitable for both paved roads and occasional off-road adventures. Their robust construction ensures they handle gravel and dirt paths effectively, making them ideal for vehicles that tackle varied terrains. Evaluating how you use your vehicle helps in choosing a tire that meets these specific demands, ensuring both performance and durability.

It's important to consider the overall value when budgeting for new tires. While the initial cost of radial tires might be higher than other options, their longevity and reduced maintenance needs often make them a cost-effective choice in the long run. Balancing immediate expenses with future savings through fewer replacements and better fuel economy is a smart strategy for selecting the right tire.

Shopping for Quality Radial Tires

When searching for radial tires, comparing tread warranties among manufacturers can offer valuable insights into expected performance and reliability. A comprehensive warranty often reflects a manufacturer's confidence in their product's durability and lifespan, guiding you toward a dependable choice.

Ensure that the tires you select are compatible with your vehicle's specifications. This compatibility is crucial for maintaining the safety and performance standards set by the vehicle manufacturer, ensuring optimal driving dynamics and tire functionality.

Customer reviews and ratings are indispensable tools for evaluating tires. Insights from other drivers provide a practical perspective on tire performance, aiding in your decision-making process. Look for consistent feedback on durability, handling, and comfort to find a tire that meets your expectations.

Understanding radial tire construction empowers you to make informed decisions about your vehicle's most important safety component. The advanced engineering behind radial tires directly impacts your driving experience, from daily comfort to long-term cost savings. When you're ready to experience the benefits of quality radial tires, we invite you to shop for tires online and find the best deals where our experts can help match you with the perfect tires for your specific driving needs.

Ready to find the perfect tires?

Search By